A visit to the Glashuette Original factory

Part 2

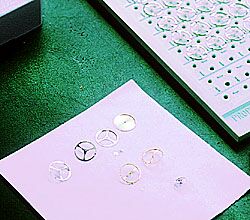

Other doors open to reveal the facilities where many of the small parts are made: wheels, drives, shafts, screws and even the balance wheels. Sometimes the parts produced are so tiny, that it is impossible to tell them apart from the waste material with the naked eye. With the exception of the springs and the jewels, the Glashuette Original factory is producing all parts of their movements inhouse, which distinguishes the company from most others in the watch production.

Here the small parts are produced |

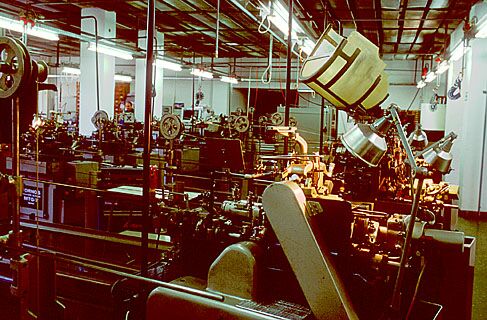

However, one has to understand that this nowadays highly praised autarchy is the result of a very peculiar political and economical development completely different from the Western European standard: As was the case in Switzerland, the Saxonian watch industry too, originally was highly dispersed and consisted of a multitude of companies, each dedicated to the production of a single category of parts. Even before the German Democratic Republic was formally founded in 1949, these companies were socialized and collectivized into one state-owned company, bringing together all suppliers under one roof and management.

The communist Eastern Germany did not have enough stock of hard currency available to import watchparts from Swiss or West German manufacturers. Therefore as much as possible was to be produced indigenously. During the eighties even quartz oscillators for quartz watches were made in Glashuette. The only big exception was made with the production machines, which were bought in Switzerland, many of which are still in use today. |

|

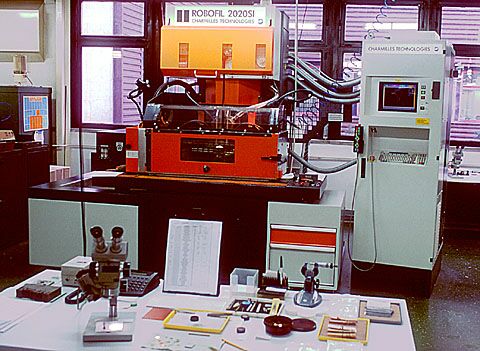

A lot more modern are the huge spark erosion machines we find in another room. Here all the fine and flat parts, which formerly were stamped or punched, are cut out from the sheets of raw material by means of a powerful electrical charge. On a monitor nearby we can follow the wire and the spark, cutting out a delicate swan-neck regulator; this procedure lasts several minutes, so it is understandable, that with only a few of these sophisticated machines the production numbers cannot be high.

We leave behind the noisy production halls, passing long and empty corridors. Every now and then a door opens and a worker comes into sight, tugging a small handcart loaded with nothing but some watchparts. After a friendly greeting he disappears again, continuing his way to another department in need of the parts he is transporting. Sometimes I have the impression of walking through some abstruse administration building, in which individual files are carried from room to room, floor to floor. The lack of an internal transporting system makes this handwork necessary, Mrs Boehme explains. But the complete reconstruction of the building is planned and will take place the following year. A modernized architecture with a glassy façade will bring the end to this and some other peculiarities. |

Sparc erosion machine |

Perspective view of the planned factory rebuild. Picture © Glashuette Original |

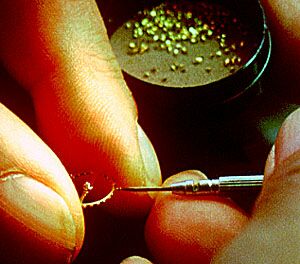

The next departments we visit on our tour are dedicated to checking and decorating the parts previously produced, as well as the production of some subassemblies. While several employees are checking all wheels for their proper balance, a colleague uses a microscope to screw the tiny screws into the balance wheels with impressive routine. At nother workplaces the baseplates and bridges are decorated with special grindings, the Glashuette stripes, which happen to be identical to the well-known Geneva stripes. A lot of handicraft is involved when Glashuette Original movements have to be decorated: Trained hands apply all the different grindings, and with their experienced eyes the employees set all the circles and stripes on their proper locations with perfect evenness. Edges are bevelled and screwheads polished; the high precision with which the specialists treat each individual part is obvious. |

Checking the balance wheels for flaws |

Quality control of all parts before assembly |

|

Balance wheels Movement cal. 39 of the Senator series Picture © Glashuette Original |

The weight screws are screwed into the balance wheel |

Baseplates are decorated |